The DIGITIG 200 AC / DC MULTIPULSE welding machine is a device of the latest generation, made in IGBT technology and equipped with digital control . It is used for manual TIG welding of steel and non-ferrous metals with direct and alternating current. It also has the option of MMA welding (with a coated electrode).

The device enables full digital regulation and control of the welding parameters of the arc and pulse characteristics as well as the choice of the AC waveform .

It has a voltage ignition HF , the ability to control mode dwutaktu and czterotaktu and spot welding . It is also possible to save 20 sets of pulse and welding current parameter settings.

During MMA welding, it is possible to adjust the ARC FORCE and HOT START functions .

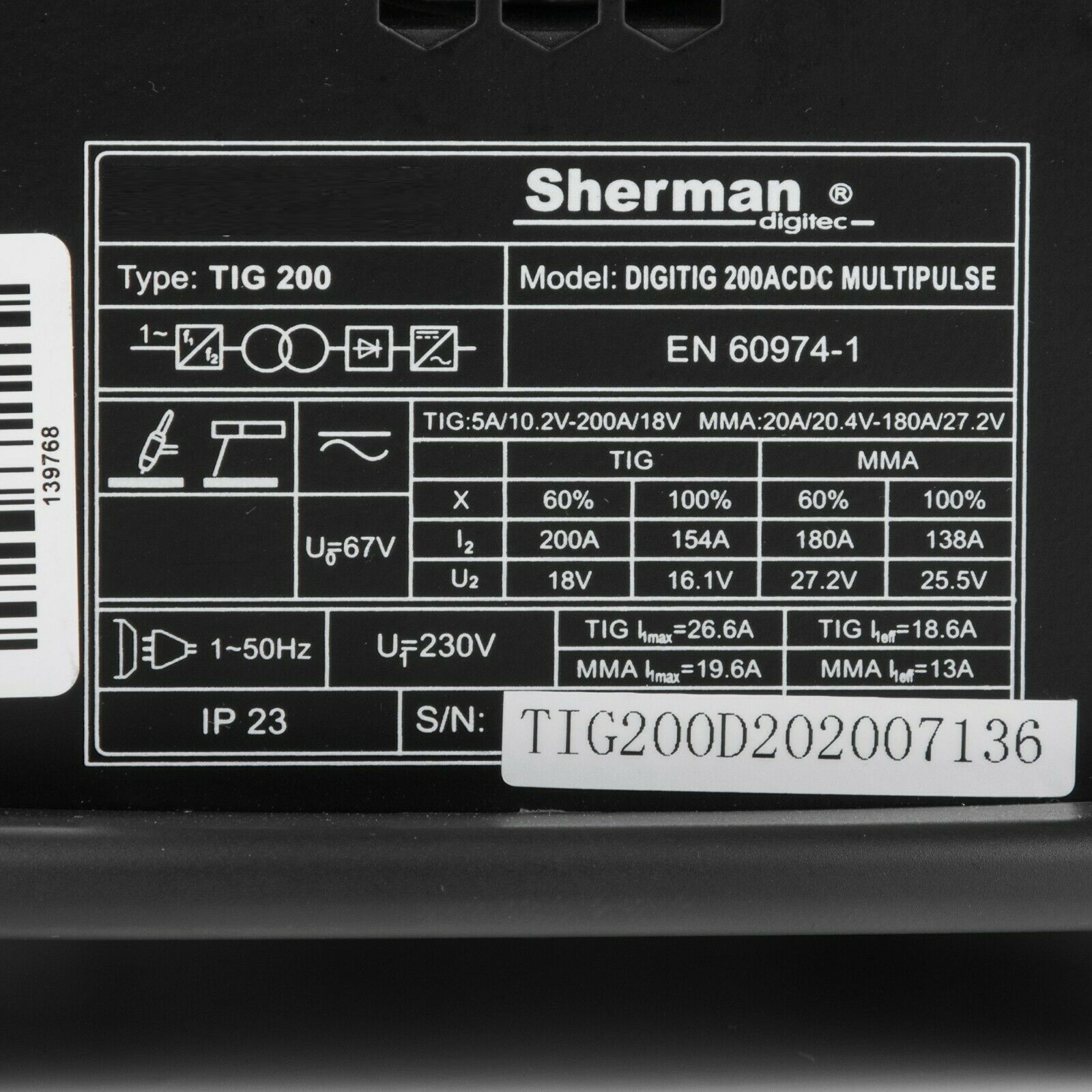

TECHNICAL DATA

Supply voltage AC 230V 50Hz

Maximum power consumption MMA: 5.7 kVA, TIG: 4.1 kVA

Rated welding current / duty cycle MMA: 180 A / 60% TIG 200 A / 60%

Rated no-load voltage 67 V

Maximum current consumption MMA : 26.6 A, TIG 18.6 A

Network protection 25 A.

Weight 15 kg

Dimensions 510 x 210 x 380 mm

Protection degree IP23

RANGES OF PARAMETER ADJUSTMENTS

ARC FORCE 0 – 100 A.

HOT START 0 – 100 A

Gas pre-flow 0.1 – 15 s

Gas post-flow 0.1 – 15 s

Current ramp up 0 – 15 s

Current downslope 0 – 15 s

Initial current 5 – 200 A.

Welding current MMA: 20 – 180 A TIG: 5-200 A

Base current 5 – 200 A.

Crater current 5 – 200 A.

Pulse frequency 0.5 – 999 Hz

Pulse width 10 – 90%

AC frequency 1 – 250 Hz

AC balance 15 – 50%

Spot welding 0.1 – 15 s